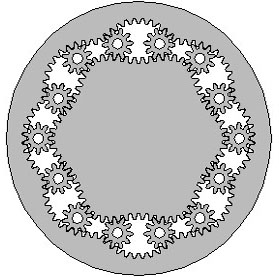

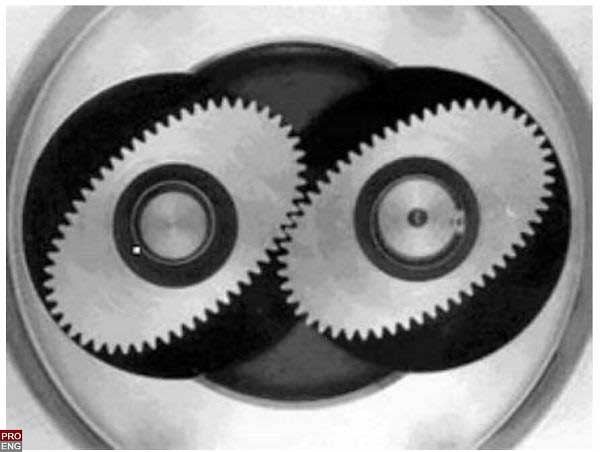

assuming the gear teeth are very small), let r 1 ( θ 1 ) is a constant of integration. Ignoring the gear teeth for the moment (i.e. In most cases, general gears defined by basic parameter (module, cog. Because of complicated geometry, NCGs are most likely spur gears and molding or electrical discharge machining technology is used instead of generation. Keywords: gear, cogwheel, noncircular gear, nonlinear rack, cog profile. Generally NCG should meet all the requirements of regular gearing, but in some cases, for example variable axle distance, could prove impossible to support and such gears require very tight manufacturing tolerances and assembling problems arise. For this reason NCGs in most cases are not round, but round NCGs looking like regular gears are also possible (small ratio variations result from meshing area modifications). In the case of non-circular gears, those circles are replaced with anything different from a circle.

We have worked with companies worldwide, helping them to increase production and raise their levels of quality. has been manufacturing elliptical and other non circular gears for companies large and small, in a wide variety of industries. Ī regular gear pair can be represented as two circles rolling together without slip. For over fifty years, Cunningham Industries, Inc. Delgear is a computer software package for the integrated design and manufacture of generalized gear pairs. Common applications include textile machines, potentiometers, CVTs ( continuously variable transmissions), window shade panel drives, mechanical presses and high torque hydraulic engines. Non-Circular Gears - Circular - Circular Dichroism - Circular Circus - Circular Cities. While a regular gear is optimized to transmit torque to another engaged member with minimum noise and wear and with maximum efficiency, a non-circular gear's main objective might be ratio variations, axle displacement oscillations and more. Cunningham Industries' non-circular gearing expertise has been responsible for solving numerous manufacturing and production challenges, several of which are described below.A non-circular gear ( NCG) is a special gear design with special characteristics and purpose. While a regular gear is optimized to transmit torque to another.

Non-circular gears are used to improve the function, versatility, and simplicity of many mechanical processes. A non-circular gear (NCG) is a special gear design with special characteristics and purpose.

102 Lincoln Avenue Stamford, CT 06902-3121 Phone: 203 324-2942 GearsĬunningham Non-Circular Gears - Typical Applications

0 kommentar(er)

0 kommentar(er)